In today’s margin-conscious environment, controlling working capital isn’t just about accounts receivable and payable—it’s about what’s sitting in your warehouse. One of the most overlooked levers of liquidity and operational efficiency? Days Inventory Outstanding (DIO).

For CFOs focused on optimizing performance, DIO is a key metric worth monitoring. It can either be a silent value drain or a competitive advantage, depending on how well it’s managed. In this blog, we’ll unpack what DIO really tells you, why it matters, and how reducing it can unlock cash flow, improve forecasting, and strengthen supply chain performance.

What is Days Inventory Outstanding (DIO)?

Days inventory outstanding is a metric that measures how many days, on average, a company holds inventory before it’s sold. It’s a key component of the cash conversion cycle and is directly tied to your ability to efficiently turn products into profit.

The formula is simple:

DIO = (Average Inventory ÷ Cost of Goods Sold) × 365

A high DIO means inventory is sitting for too long, tying up capital and increasing storage, obsolescence, and shrinkage risks. A low DIO, on the other hand, suggests substantial inventory turnover and lean operations.

But not all industries have the same benchmarks. Retail and fast-moving consumer goods (FMCG) tend to have lower DIO norms than industrial or seasonal businesses. What matters most is how your DIO compares to historical trends and those of your competitors.

Why DIO Matters for CFOs

CFOs looking to optimize working capital must understand the full scope of inventory’s impact. DIO is a vital CFO metric because:

- It ties up cash: Inventory is money sitting on a shelf. The longer it sits, the more it erodes liquidity.

- It affects forecasting: Excess or obsolete inventory clouds visibility and complicates financial planning.

- It reflects demand accuracy: Poor DIO often indicates poor forecasting, production misalignment, or sales underperformance.

- It impacts profitability: Carrying too much inventory increases holding costs, which eat into margins.

Improving DIO gives CFOs breathing room—especially in capital-constrained environments or during expansion planning. Freeing up cash from inventory can help fund growth without tapping external financing.

How to Reduce DIO Without Sacrificing Service

Reducing days inventory outstanding isn’t about slashing stock and crossing your fingers. It’s about better data, better coordination, and more innovative processes across procurement, finance, and operations.

Here are five practical strategies CFOs should consider:

1. Improve Demand Forecasting

Utilize historical data, market trends, and sales data to refine your forecasting. AI and predictive analytics can identify seasonal patterns, detect anomalies, and accurately project inventory needs.

2. Tighten Supplier Lead Times

Collaborate with vendors to reduce procurement cycles. If you’re holding excess safety stock due to long lead times, renegotiating terms or diversifying suppliers could reduce your inventory burden.

3. Adopt Just-in-Time (JIT) Inventory Models

JIT isn’t just for manufacturers anymore. Many businesses are shifting to leaner inventory models to reduce DIO. This requires strong supply chain reliability, but can drastically reduce excess stock.

4. Integrate AP and Inventory Data

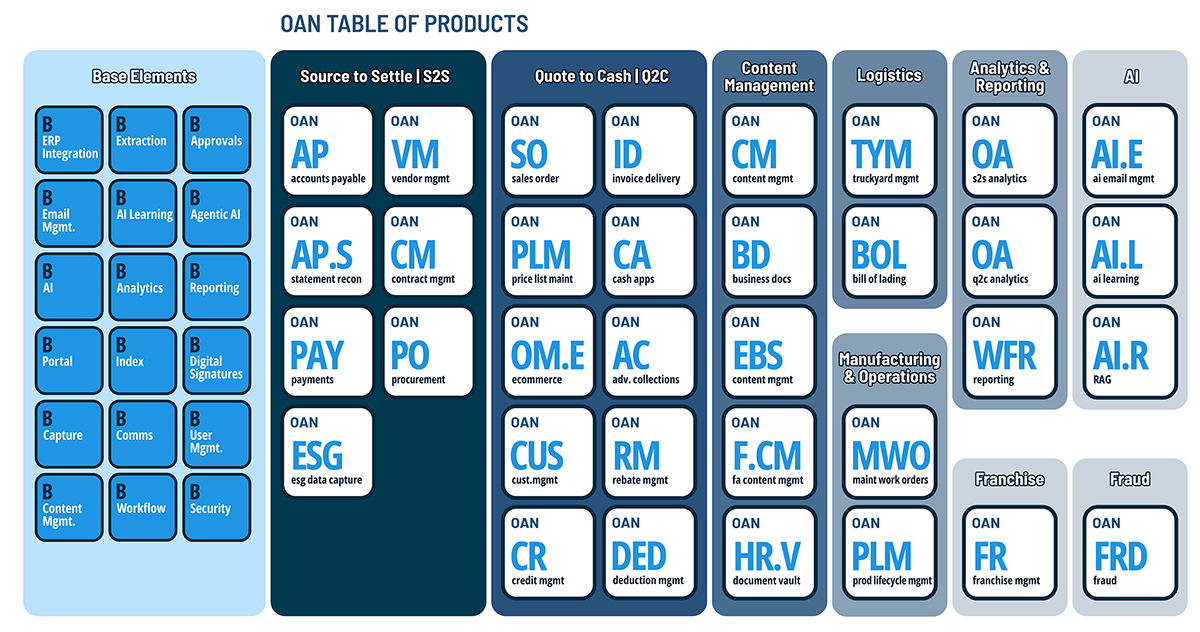

This is where AP automation can add surprising value. With connected systems, you gain real-time visibility into inventory turnover, supplier payment cycles, and the impact on working capital. Platforms like oAppsNET enable CFOs to align procurement and finance for more informed inventory decisions.

5. Regularly Review Product Lifecycle and Obsolescence Risk

If certain SKUs are dragging down your DIO, it’s time to trim the fat. Regular SKU rationalization helps prevent inventory bloat and reallocates resources to high-turnover products.

How AP Automation Helps Optimize DIO

It might not be the first place you look, but AP automation can play a pivotal role in reducing DIO. By automating invoice approvals and supplier payments, CFOs can create more agile procurement workflows, sync payment cycles with delivery schedules, and prevent over-ordering.

oAppsNET’s solutions offer centralized dashboards where finance leaders can view real-time inventory and payables data side by side. This transparency helps finance and supply chain teams collaborate, adjust ordering based on cash flow or sales velocity, and maintain optimal stock levels without tying up unnecessary capital.

DIO in Context: Don’t Optimize in Isolation

While reducing DIO is a clear win for liquidity, it’s essential to consider it as part of the broader working capital picture. Optimizing DIO at the expense of customer satisfaction or production continuity can have unintended consequences. The goal isn’t the lowest possible DIO—it’s the right DIO for your business model, market, and risk tolerance.

CFOs should track DIO alongside days sales outstanding (DSO) and days payable outstanding (DPO) to understand the full cash conversion cycle. Together, these CFO metrics provide a 360-degree view of working capital health.

DIO as a Strategic Lever

Inventory may not be glamorous, but it’s one of the most significant untapped sources of cash sitting on your balance sheet. Days inventory outstanding isn’t just an operational stat—it’s a strategic lever for CFOs to boost liquidity, reduce risk, and drive more intelligent decision-making.

With the right tools and a cross-functional mindset, CFOs can transform DIO from a reporting obligation into a performance driver.

Want to reduce DIO and optimize your working capital strategy? Contact oAppsNET to learn how automation, integration, and real-time insights can drive results.