In modern supply chains, speed is strategy. Whether managing raw materials inbound or finished goods outbound, delays at the yard gate can undermine even the most optimized warehouse or ERP system. That’s why more enterprise leaders are turning their attention to a previously overlooked source of friction and opportunity: truck yard management.

Truck Yard Management Software (YMS) is emerging as a crucial link between logistics operations and enterprise finance goals. By streamlining the movement, tracking, and coordination of trucks at facilities such as manufacturing plants or distribution centers, YMS solutions are helping CFOs and operations leaders reduce detention fees, optimize throughput, and improve real-time visibility across the supply chain.

What Is Yard Management and Why Does It Matter?

At high-volume facilities—think Amazon fulfillment centers, Walmart distribution hubs, or industrial manufacturing campuses—yard operations involve a constant flow of trailers, shipments, and gate movements. But when yard processes rely on clipboards, phone calls, and radio dispatching, the result is often chaos:

- Inbound trucks queuing for hours without clear instructions

- Outbound loads delayed due to misplaced trailers

- Manual logs leading to data entry errors and limited visibility

- Detention fees stacking up as drivers wait for dock assignments

These inefficiencies result in significant financial consequences, particularly when multiplied across hundreds of daily shipments. A digitally managed yard becomes a strategic asset, helping to streamline inbound/outbound logistics, reduce costs, and unlock data-driven coordination between procurement, warehousing, transportation, and finance.

The Strategic Case for Truck Yard Management Software

For finance leaders, the yard is no longer just an operational concern. It touches cost control, performance metrics, risk management, and vendor satisfaction. Here’s how Truck Yard Management Software supports broader enterprise goals:

1. Operational Efficiency and Throughput Gains

Manual yard coordination creates unnecessary dwell times. A modern YMS automates:

- Gate check-in/check-out via kiosks, RFID, or mobile apps

- Real-time trailer location tracking

- Dock scheduling and trailer assignments

- Yard jockey task dispatching

This eliminates bottlenecks and improves dock-to-stock and stock-to-ship cycle times, ultimately enabling higher throughput without requiring additional headcount or yard real estate.

2. Cost Reduction and Detention Fee Avoidance

Idle trucks = wasted money. Carriers often charge detention fees after a grace period (e.g., 2 hours). Without accurate timestamps and workflows, those charges go uncontested—or worse, undetected.

YMS platforms log every trailer movement and timestamp, allowing finance teams to track accessorials, validate carrier invoices, and reduce payment errors.

3. Data-Driven Visibility Across Supply Chain Functions

Truck yard data often lives in silos, disconnected from WMS, TMS, or ERP systems. A well-integrated YMS bridges this gap:

- Provides real-time status updates for inbound and outbound shipments

- Supports better coordination with procurement and warehouse teams

- Enables proactive exception handling (e.g., delays, misroutes, priority loads)

Finance teams benefit too: with timely data on shipping schedules and inventory movements, they can more accurately manage working capital, accruals, and supply-side liabilities.

4. Stronger Carrier and Vendor Relationships

Delays and confusion at the yard frustrate carriers—and ultimately hurt supplier satisfaction. YMS provides:

- Pre-scheduled appointments

- Automated alerts and load instructions

- Faster turn times and transparency

The result? Improved service levels, reduced SLA breaches, and enhanced collaboration with 3PLs and carriers.

5. Audit-Ready Documentation and Compliance

Whether it’s ESG reporting, safety inspections, or customs compliance, traceability matters. YMS systems provide:

- Time-stamped audit trails of every trailer movement

- Electronic documents for inspections or regulatory filings

- Standardized workflows for incident reporting and investigations

This reduces risk exposure and supports CFOs in meeting compliance obligations and sustainability reporting standards.

Where YMS Fits in the Broader Digital Transformation Landscape

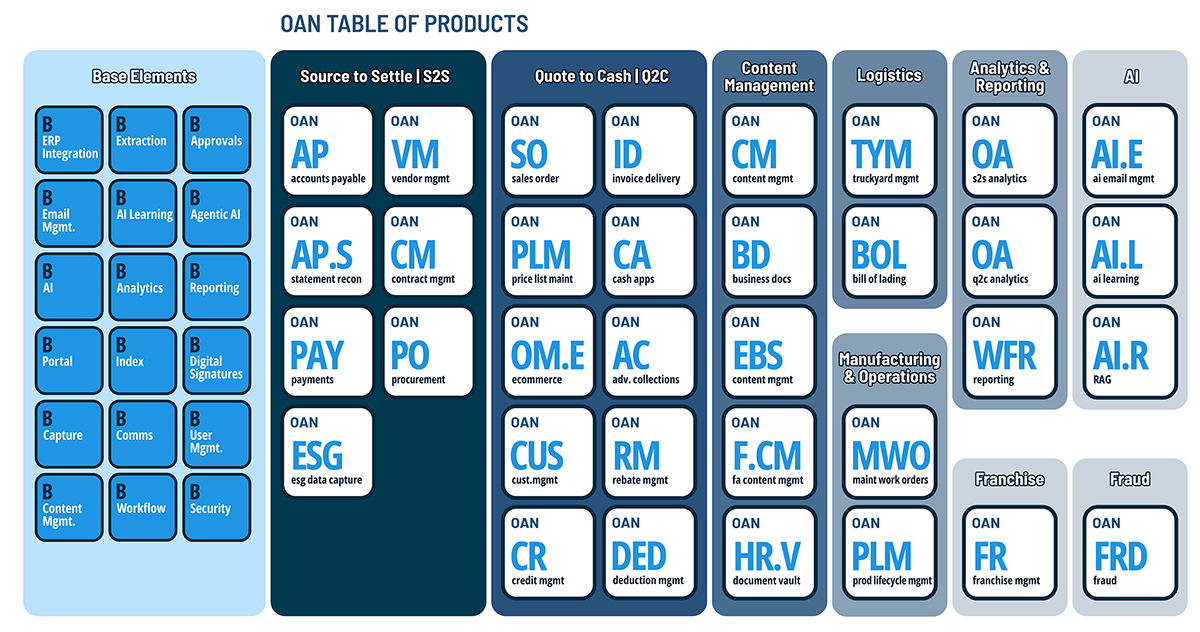

If you’re investing in AP automation, contract lifecycle management, or supply chain digitization, YMS is a natural next step.

It’s not just about reducing yard chaos—it’s about integrating the yard into your ERP and logistics tech stack to enable real-time coordination across the entire supply chain.

For example:

- Linking YMS with procurement and inventory planning tools enables the prioritization of dock slots based on order urgency.

- Connecting YMS with AP systems ensures detention invoices are verified before payment.

- Integrating with TMS or carrier portals supports seamless scheduling and real-time tracking of expected arrivals.

What to Look for in a YMS Platform

Choosing the right Yard Management Software depends on your facility’s complexity, shipment volumes, and integration needs. Key capabilities include:

- Automated gate check-in and check-out

- Real-time trailer and dock tracking

- Mobile workflows for yard jockeys

- Integration with ERP, WMS, and TMS

- Analytics dashboards for dwell time, carrier performance, and other key metrics

- User-friendly scheduling and exception management tools

Bonus points if the platform supports AI-driven recommendations, such as dynamic rescheduling or predictive congestion alerts.

How oAppsNET Clients Stand to Benefit

While oAppsNET primarily focuses on Oracle-centric finance transformation, our clients operate at the intersection of finance, procurement, and supply chain. Yard operations often become the missing link between back-office automation and frontline logistics.

Bringing yard data into the fold means:

- Cleaner cost accounting

- Fewer invoice disputes

- Better supplier relationships

- Improved cash flow visibility

- Stronger audit trails for logistics operations

For CFOs aiming to optimize every lever of cost and efficiency, investing in tools like YMS completes the picture. If your supply chain initiatives stop at the warehouse door, you’re leaving value on the table. Truck Yard Management Software is no longer optional for high-volume operations—it’s a core enabler of digital supply chain performance and financial precision.

The yard is where finance, logistics, and technology converge. Let’s bring it into the strategy conversation together.